VCRP™ for Pharma/Biotech

Multi-Tier / Site Visibility, Planning and Management

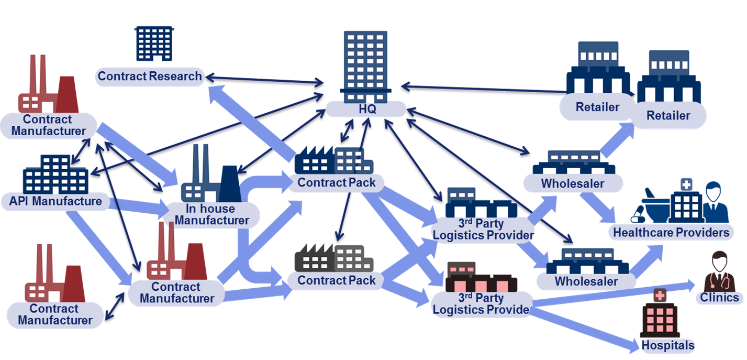

Pharma and Biotech brand owners face huge challenges planning and managing their multi-tier in/out bound value chains. Firms find it difficult to achieve real time visibility from key sub-suppliers through in-house or contract manufacturing to logistics down through master distributors or direct distribution to end users. Owners have growing traceability and/or serialization requirements.

Leaders are looking to synchronize demand signals with supply plans / processes across end to end value streams segmented by market channels. They need agile support for constantly evolving business processes with channel / partner specific processes, yet require central control and management. They wish to see consolidated network wide data, yet be able to plan and execute daily down to single sku/site level, but they do not want to replace existing validated systems nor can they demand that partners make costly investments to participate.

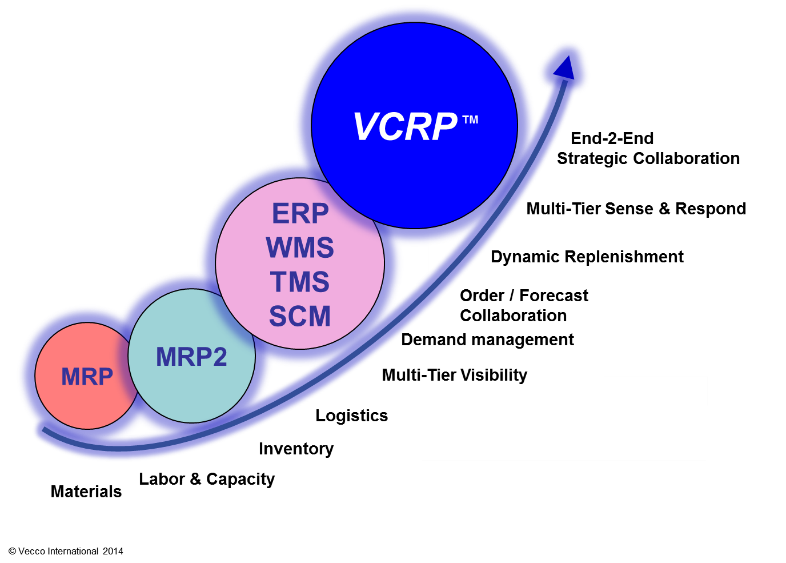

Leaders seek a next gen platform to unify their existing enterprise solutions and their partner’s information /process flows into a unified value chain operating platform, synchronized daily.

How can you implement these solutions cost effectively?

VCRP delivers a modern, purpose built multi-tier value chain “operating system” with visibility, planning, fulfillment and demand visibility and cost effective multi-party inventory management. View critical data from any participating site or partner, see plans and actuals and drill down to individual transactions as needed. Collaborate with partners to choose the best options. Create or change plans and then synchronize them back for execution in their own or partner’s systems at all the required partners or sites automatically. Daily activity is aggregated up in configurable time buckets for planning and aggregated business plan data is broken down weekly and reconciled to actual activity.

We manage lot controlled and serialized products such as drugs, devices and other items subject to effectivity dates, expiration, traceability, and recall requirements. VCRP supports the emerging compliance requirements for lot and serial traceability compliance.

We offer specific applications to support multi-tier drug manufacturing and distribution needs, VCRP provides agile event response capability, such as recovery from a catastrophic supplier failure, or materials shortage problems, enabling transformative levels of customer satisfaction, without requiring changes to your ERP solution or to your partner’s existing IT investments. Leverage your enterprise systems investments into a value chain solution cost effectively.

See, Plan and Manage Value in Real-time, from End-to-End

Vecco enables / manages compliance in these challenging environments. Item and lot traceability / visibility can extend from root ingredient batch to finished, packaged product delivered to a specific user.

VCRP Real-time Synchronization of Multi-Enterprise Business Processes

Dynamic response to continual changes of demand and supply is particularly challenging across a multi-tier or highly outsourced supply chains. VCRP delivers accurate and timely End-to-End visibility, configurable business workflows, and a complete suite of collaborative supply and demand management solutions. We enable customers to attain “Omni-Site” view and management of true aggregated demand and inventory.

VCRP Secure platform and dynamic workflow processes

Complex many-to-many relationships are decoupled from the underlying disparate systems and re-coupled into many-to-one relationships. This architecture reduces complexity and allows the number of business partners to scale easily. Security is highly granular, down to the site, user, role, and item.

- Agile to constant business process changes, in a secure, easy to control manner with highly

- Fast deployment and rapid ROI. Solutions can be configured and affordably deployed in 120 days

Supply Chain 4.0 enabling the ‘Digital Enterprise’ and Industry 4.0

The real value of the "Digital Enterprise" movement & Industry 4.0 can only be realized unless it is encompassed and orchestrated by parallel automation / Digitization of the 'Supply Chain' delivery mechanism. "Global supply chain flows must become increasingly...