VCRP™ Benefits

Business Benefits

The research is clear:

Overall Value Chain Performance Ultimately Determines your Business’ Performance and Value.

Vecco uniquely enables companies to intelligently respond to the constant change in supply, demand, products and partners resulting in:

- Improved perfect order fill rates / Service levels

- Increased inventory turns

- Increased revenue while lowering execution costs

- Increased responsiveness, agility and resilience

- Abatement of supply chain event risk.

VCRP™ creates end-to-end supply, demand and logistics visibility and multi-enterprise orchestration without requiring changes to existing IT investments. This allows firms to maximize revenue potential while minimizing operating costs for global businesses.

It provides an agile event response capability which enables transformative levels of business performance and service levels, creating a time-based competitive advantage.

Deloitte, for example, has identified systemic approaches to Supply Chain issues as critical.

“Digital supply networks and analytics can be powerful enablers …The risks from not “connecting the dots” through available data can be significant”.

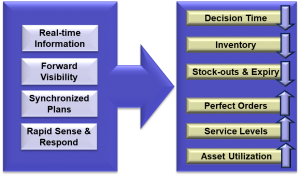

The VCRP’s unique combination of real-time Visibility, Planning and Execution capabilities provides numerous specific benefits:

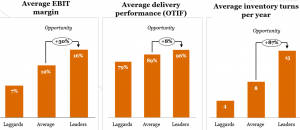

PWC quantified these potential financial benefits associated with improved end-to-end supply chain performance.

To paraphrase Peter Drucker, if you can’t measure it, you can’t improve it.

VCRP provides Benchmarking tools that enable clients to measure the before and after supply chain performance and the associated ROI and opportunities for improvement.

One very important benefit that is difficult to quantify however, is dramatically improved collaboration with your key trading partners. Clients can facilitate shared information exchange that benefits all parties by providing insight into current issues, future plans and collaboration opportunities.

Clients can monitor critical performance data from any partner, drill down to individual metrics and transactions and create or modify them as needed. Alert information is fed back for adjustment and execution automatically. This traceability and visibility can extend from root ingredient batch to finished packaged product delivered to a specific user.

Supply Chain 4.0 enabling the ‘Digital Enterprise’ and Industry 4.0

The real value of the "Digital Enterprise" movement & Industry 4.0 can only be realized unless it is encompassed and orchestrated by parallel automation / Digitization of the 'Supply Chain' delivery mechanism. "Global supply chain flows must become increasingly digital and integrated, and end-to-end data will be driven in real-time,...