CPG / Food & Beverage

Large global consumer goods companies with a combination of internal manufacturing and outsourcing must effectively predict demand and manage complex multi-national supply chain networks to ensure on-time in full delivery to their retail customers such as WalMart, CostCo, Amazon, QVC. etc. A CPG company must tightly schedule production reflecting the time actually required to produce its finished goods. This demands strong forecasting capabilities, and a very tightly controlled end-to-end supply chain.

Most supply chain planning platforms fall short in addressing the complex needs of food manufacturers and ingredient suppliers. Vecco International’s VCRP™ (Value Chain Resource & Response Planning) combines supplier-, production- and distribution-level planning and execution into one integrated solution. It provides deep visibility into raw & packaging material suppliers, and co-manufacturers, while also managing fulfillment to downstream channels, delivering to retail and QSR customers, or whole-sale distributors. Vecco provides that mission critical end-to-end visibility and response capabilities to manage inventory and fulfillment. Projected inventory is automatically recalculated and compared to minimum and maximum targets as supply or demand events are recorded. User defined exception alerts will automatically be triggered when alert conditions are met. If the automated agent-solver is unable to resolve the problem within user-defined policies and constraints, alerts will be triggered for human intervention. Flexible hierarchies allow OEMs to evaluate performance at different aggregations of location, product and time.

Crucially, Vecco innately supports batch and process manufacturing – key to the food industry. We support collaborative planning and execution both with customers and suppliers. We provide available to promise and capable to promise functionality for a customer order based on approved sourcing for a sales area. Once an order is accepted, the system will “peg” allocated inventory lots to an order based on required attributes and reserve this inventory.

Once the product has been manufactured, getting the product into the hands of the retailer/end user is a critical process. Vecco provides detailed visibility and tracking of shipments in the network to shippers, and customers (self-service look-up to customers). Alerts are generated to indicate challenges such projected early and late arrivals. The system will generate a shipment notice (ASN) when a shipment is made and capture the corresponding receipt notice (GRN). An automated process matches ASNs & GRNs and generates alerts for mismatches.

The system closely monitors expiry dates allowing CPG companies to properly sequence lot shipments. Warehousing, cold chain monitoring and logistics are also tightly managed through integration with the WMS, 3PL and TMS systems.

Vecco empowers companies to monitor and manage their supply chain performance. The platform provides visibility into all user defined key supply chain performance metrics and provides flexible score carding capabilities to monitor partner performance.

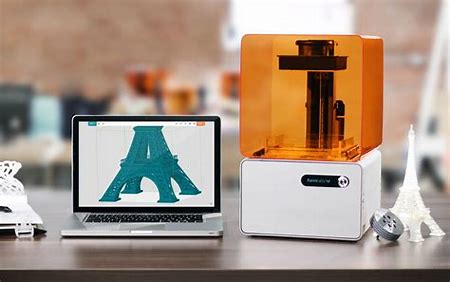

Formlabs Leverages Vecco to Manage Global Demand, Supply, and Inventory Operations

Leading 3D printer manufacturing company deploys next generation supply chain management system to orchestrate supply and demand across their rapidly expanding global supply chain. MALVERN, PA. Vecco International, provider of an advanced end-to-end cloud-based...