News

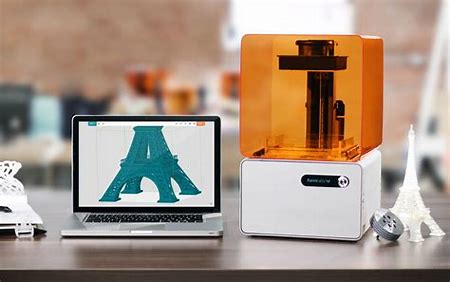

Formlabs Leverages Vecco to Manage Global Demand, Supply, and Inventory Operations

Leading 3D printer manufacturing company deploys next generation supply chain management system to orchestrate supply and demand across their rapidly expanding global supply chain. MALVERN, PA. Vecco International, provider of an advanced end-to-end cloud-based supply chain management solution, enables Formlabs, the industry...

Is Lack of Real-Time Synchronized Data Threatening Your Ability to Service Your Customers?

Your Business has just received great news: your sales for a specialty item manufactured in-house are through the roof. In fact, they’re way over forecast. However, as the Supply Chain Planner, there’s bad news: you’re short on production capacity and raw materials. Coordinating your global supply...

Supply Chain 4.0 enabling the ‘Digital Enterprise’ and Industry 4.0

The real value of the "Digital Enterprise" movement & Industry 4.0 can only be realized unless it is encompassed and orchestrated by parallel automation / Digitization of the 'Supply Chain' delivery mechanism. "Global supply chain flows must become increasingly digital and integrated, and end-to-end data will be driven in real-time,...

Vecco Named a Supply Chain “Cool Vendor” by Gartner

Vecco International, a technology leader in value chain visibility, planning, and response management solutions, has been named in Gartner’s report, “Cool Vendors in Supply Chain Planning.” Vecco officials believe the company’s inclusion in the report confirms the value of its leading-edge technology and ability to rapidly configure...

The World is Flattening – Let’s Get Moving!

Global flattening and the exponential advances in technology are revolutionizing the way we live and do business! This is an era where mind boggling advances in a new digital infrastructure, changes in public policy and the effects of globalization are enabling unknown companies to emerge overnight and dominate industries using...

The Refrain is the Same: Can You See Me Now? – Supply Chain Visibility

Every year there are several surveys asking supply chain executives to rank the challenges they face. And, for as long as I can remember, supply chain visibility ranks at or near the top. This year’s reincarnation of the control tower metaphor is being applied to supply chain visibility. Can you see me now? If it’s so critical, why...

Responsibility Lies with Leaders – Aligning Technology to Business Operations

First published in the Lean Management Journal (LMJ) and republished here with permission. When it comes to sustainably and profitably growing an organisation in the face of changing market conditions, Roddy Martin identifies various ‘disconnects’ within these initiatives. To understand and manage...

Collaborative Supplier Relationships – Best Practices

Collaboration with business partners can yield significant benefits including increased supply assurance, reduction in latency and lower inventory levels, faster product innovation cycles, increased flexibility to respond to change and increased revenue. While the results can be dramatic, not all attempts to foster collaborative...

Supplier Collaboration Requirements

Business Is Changing - FAST In today's fast-moving and highly interdependent global marketplace, companies are increasingly reliant on complex networks of trading partners, suppliers and outsource service providers to succeed. How effective they are at getting their partners to work together as a seamless, high-performing value chain...

21st Century Health Care Value Chain Improvement Opportunities

Health Value Chain participants (Medical materials and device manufacturers, traditional and biologic drug producers, their distributors and the healthcare systems that use them), struggle with opaque and inefficient value chains. These can stretch across 5 or more tiers of sub-supplier to OEM thru distributors to the final point of use...

Ferrari Group – Vecco, a unique platform for Multi-Tier Collaboration

We're happy to share a post on Supply Chain Matters, written by Bob Ferrari, Ferrari Consulting and Research Group: "When I was an industry analyst at AMR Research covering the supply chain planning area, I had the opportunity to evaluate and participate in the market introduction of many innovative technology companies. Some were borne...

Benefits of Vecco Control Tower in Life Sciences – Part 5

Supply Chain Alerting and Event Management Scenario Name: Supply Chain Event Management Industry Segment: Drug, testing supply and medical device manufacturing companies with a strong need for: Dynamic detection, analysis and resolution of a broad range of business problems along their end-to-end, global supply chain. Awareness of the...

Benefits of Vecco Control Tower in Life Sciences – Part 4

Product Fulfillment Improvement in a Multi-tier Distribution Environment Scenario Name: Collaborative Fulfillment Improvement Industry Segment: Companies manufacturing make-to-stock products that are distributed through a multi-tier network. Capital intensive industries (with constrained manufacturing capacity) with volatile demand...

Benefits of Vecco Control Tower in Life Sciences – Part 3

New Customer Capture enabled by End-to-End Value Chain Collaboration Scenario Name: End to End Supply Chain Collaboration Department(s): Supply Chain, Procurement, Planning, IT, Account Managers User: Buyers, Supply Managers, Operations and Fulfillment Planners, Sales Managers, Marketing Managers Economic Buyer: VP of Fulfillment...

Benefits of Vecco Control Tower in Life Sciences – Part 2

International Licensee Royalty and Service Performance Compliance Scenario: A brand owner licenses production of certain of its major over the counter medicine brands to foreign manufacturers. It is to be paid royalties on the volume of medicine. However, the brand owner has some history of poor royalty reporting in past relationships...

Benefits of Vecco Control Tower in Life Sciences – Part 1

Product Traceability and Analysis In Case of Potential Defects Across Multiple Supply and Distribution Tiers Be capable of tracing materials and process events contained in drugs and or medical devices from root supplier through production and multiple tiers of distribution to final point of sale, and to be able to immediately recall...